Why Does Autoclave Tape Change Color? Understanding the Science Behind Sterilization Indicators

Release time: 2025-12-26

In medical, dental, and laboratory settings, ensuring the sterility of equipment is a matter of safety and precision. One of the most common tools used to verify this process is autoclave tape. But have you ever wondered exactly why autoclave tape changes color?

Understanding the mechanism behind this visual shift is crucial for selecting the right products from a reliable autoclave tape supplier. Tianrun will dive into the chemistry, the process, and the importance of using high-quality indicators.

The Chemistry of Color Change: Lead-Free Indicators

The primary reason autoclave tape changes color (typically from off-white or yellow to dark brown or black) is a chemical reaction triggered by heat and steam.

The “stripes” on the tape contain a chemical indicator ink. Traditionally, these inks contained lead salts that reacted with sulfur to change color. However, modern, eco-friendly manufacturers now produce lead-free autoclave tape that uses safer organic dyes or metal-free complexes. When these specific chemicals are exposed to saturated steam at high temperatures—usually $121°C$ or $134°C$—they undergo a permanent chemical transformation, resulting in the dark stripes we recognize as a “pass” signal.

Key Features of High-Quality Autoclave Tape

Not all tapes are created equal. To ensure laboratory safety, you need a product that can withstand extreme environments without peeling or fading.

High-Temperature Resistance

A premium high-temperature resistant autoclave tape is designed to maintain its adhesive integrity even under intense pressure. It must stick firmly to various surfaces, including linen, plastic, and metal, without leaving messy residue behind after removal.

Chemical and Moisture Resistance

In complex sterilization cycles, the tape may encounter more than just steam. Using a chemical-resistant autoclave tape ensures that the indicator remains accurate even if exposed to mild cleaning agents or different sterilization gas concentrations.

Clear Visual Verification

The contrast in color change must be sharp. This allows staff to differentiate between processed and unprocessed packs at a glance, reducing the risk of accidental cross-contamination.

Why Is This Change Important for SEO and Safety?

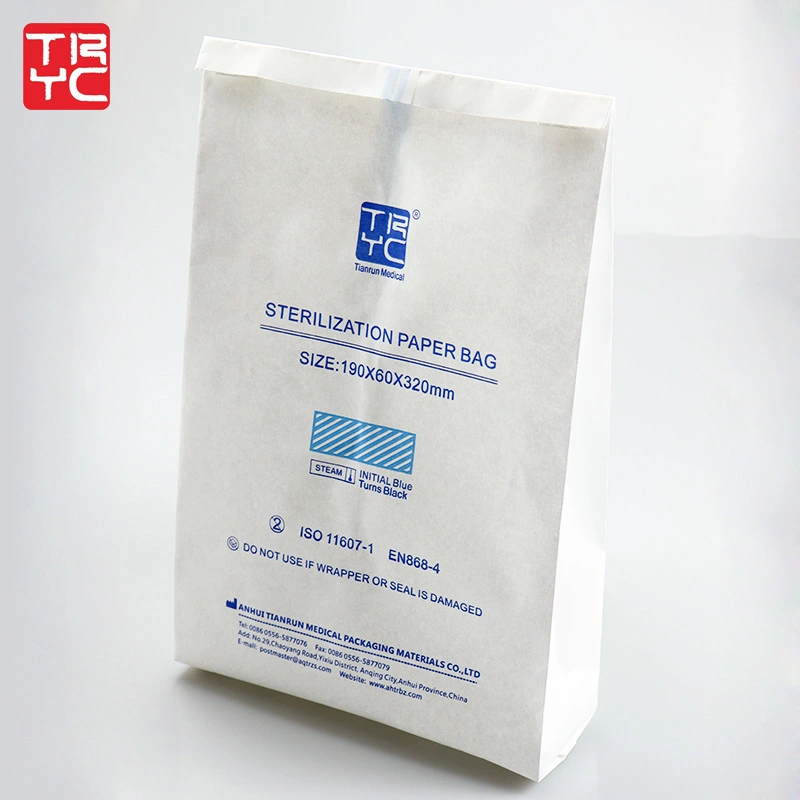

From a logistical standpoint, autoclave tape serves as a Process Indicator (Class 1). It does not guarantee that the items inside a pack are 100% sterile (that requires biological indicators), but it confirms that the package has been exposed to the sterilization process.

If you are looking for a trusted autoclave tape supplier, it is essential to verify that their products meet international standards like ISO 11140-1. Reliable suppliers provide tapes that offer:

- Consistent color transitions.

- Strong adhesion to both non-woven and paper wraps.

- Toxic-heavy-metal-free compositions.

Conclusion: Choosing the Right Tape for Your Lab

The color-changing mystery of autoclave tape is a perfect blend of chemistry and safety engineering. By reacting to the specific parameters of a steam sterilizer, it provides an immediate visual cue that protects patients and researchers alike.

Whether you are looking for high-temperature resistant autoclave tape for heavy-duty industrial use or a chemical-resistant autoclave tape for specialized clinical applications, choosing the right grade is essential for operational efficiency.

Are you looking to restock your sterilization supplies? As a leading autoclave tape supplier, we offer a range of high-performance indicators tailored to your specific needs.