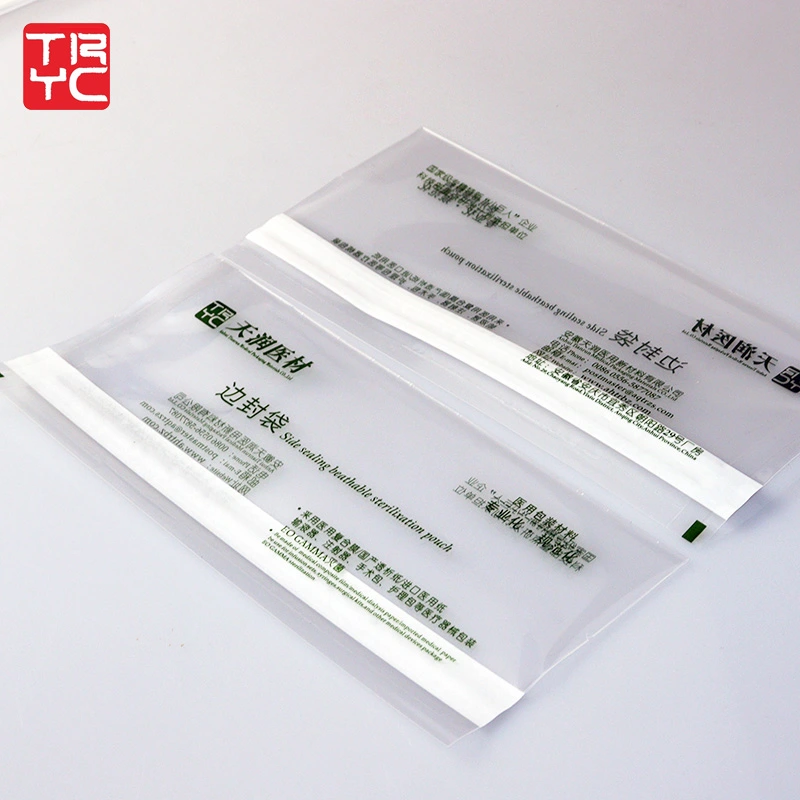

- Top Web: HDPE Film

- Bottom Web: PA/PE Film ; LDPE Film

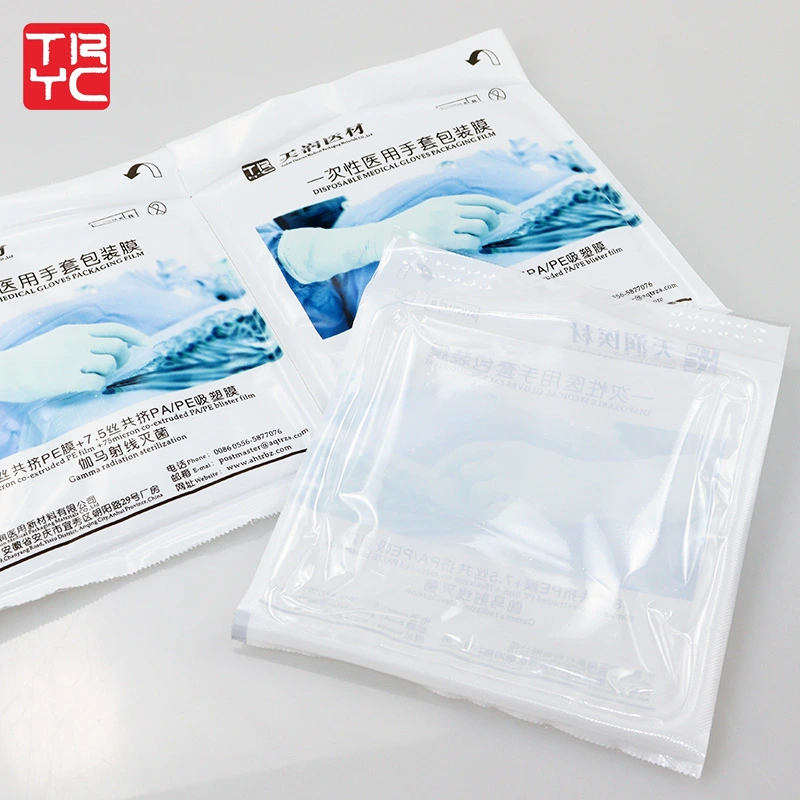

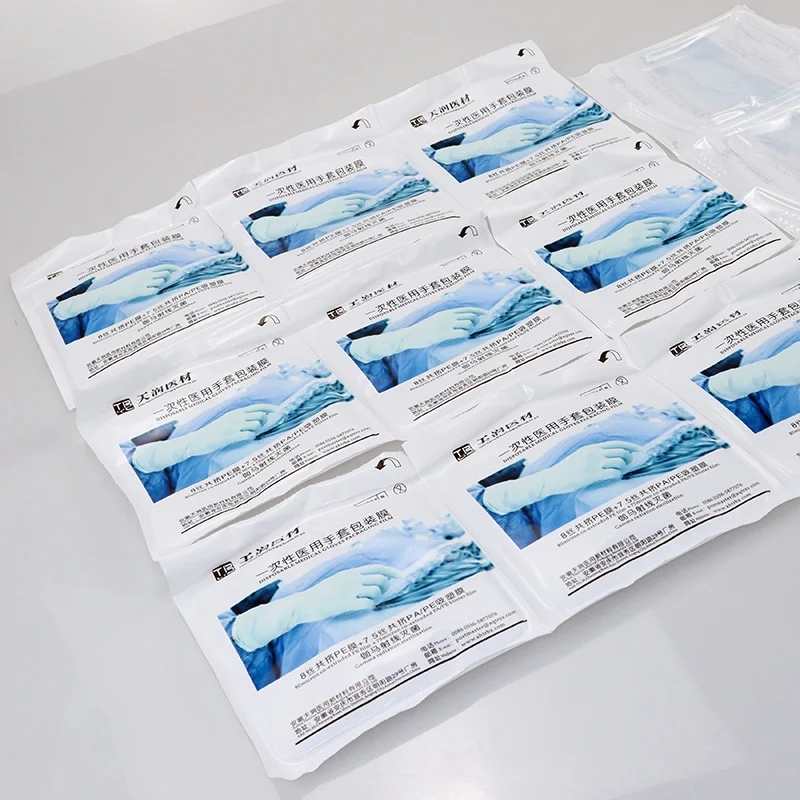

- Thermoformed glove packaging is a highly engineered solution used to securely contain and protect gloves throughout sterilization, shipping, storage, and point-of-use handling.

Description

Key Benefits of Thermoformed Glove Packaging:

Sterile Barrier Systems: Designed for HDPE film to be sealed with PA/PE film or LDPE film, these packaging maintain sterility until the point of use–ideal for surgical gloves, examination gloves and other sterile gloves.

Device Protection: Thermoformed film are engineered to prevent movement, abrasion, and contamination, ensuring safe delivery from manufacturer to end user.

Ease of Use: Clear medical flim are custom-designed for intuitive loading and opening, supporting aseptic presentation in clinical settings.

Regulatory Compliance: Thermoformed packaging is validated to meet ISO 11607 and other industry standards, supporting FDA and EU MDR requirements for medical device packaging.

Custom Fit and Functionality: Every packaging is tailored to the shape, weight, and handling needs of the device it protects, optimizing both workflow and safety.