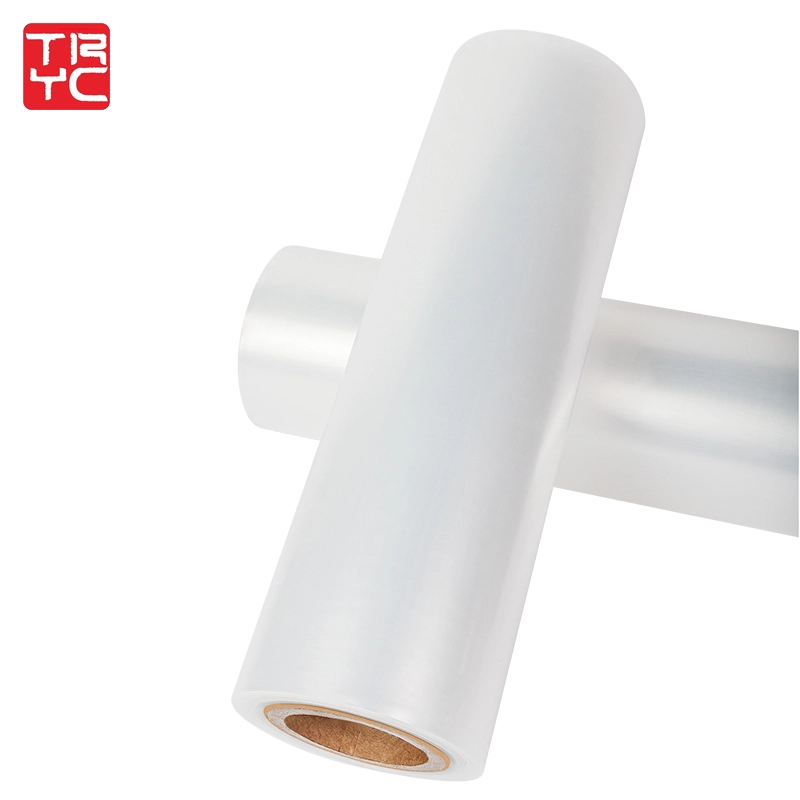

Medical thermoforming film is a specialized type of plastic film used in packaging medical devices and products. It's designed to be heated and shaped (thermoformed) into custom-fitted trays or blisters, providing a sterile barrier and protection against contamination. These films are crucial for maintaining product integrity and ensuring patient safety.

Description

Key Characteristics and Benefits:

Sterile Barrier:

Medical thermoforming films create a sterile barrier to protect devices from contamination, crucial for single-use medical devices.

High Puncture Resistance:

These films are designed to be tough and durable, with high puncture resistance to prevent damage during handling and transport.

Barrier Properties:

They offer excellent protection against moisture, oxygen, and other contaminants, which can degrade medical devices.

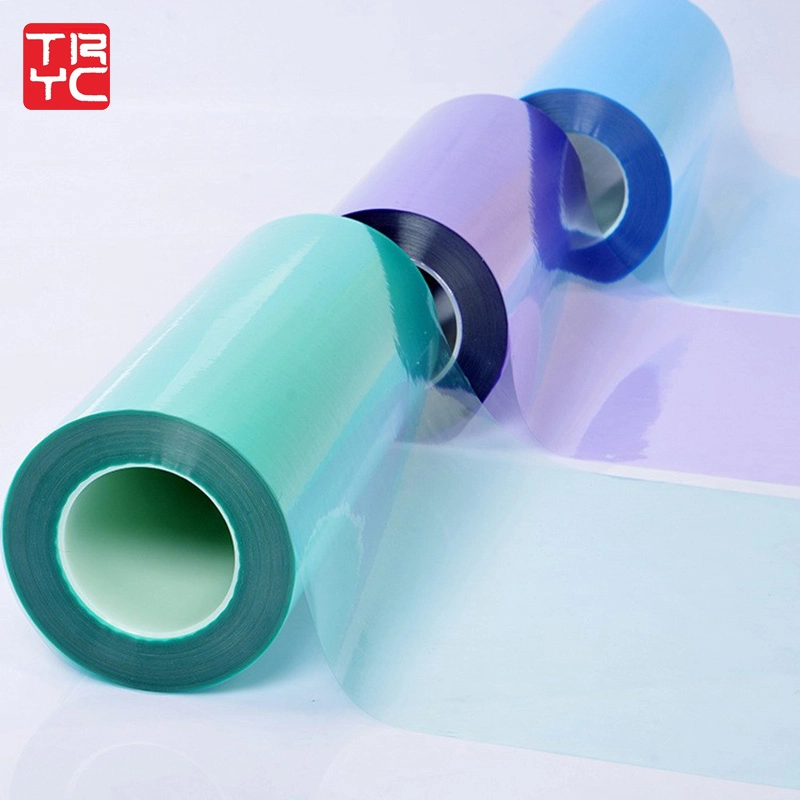

Customization:

Thermoforming allows for the creation of custom-shaped packaging to fit the specific dimensions and requirements of the medical device.

Versatility:

Suitable for a wide range of medical devices, from small instruments to larger apparatus.

Compatibility:

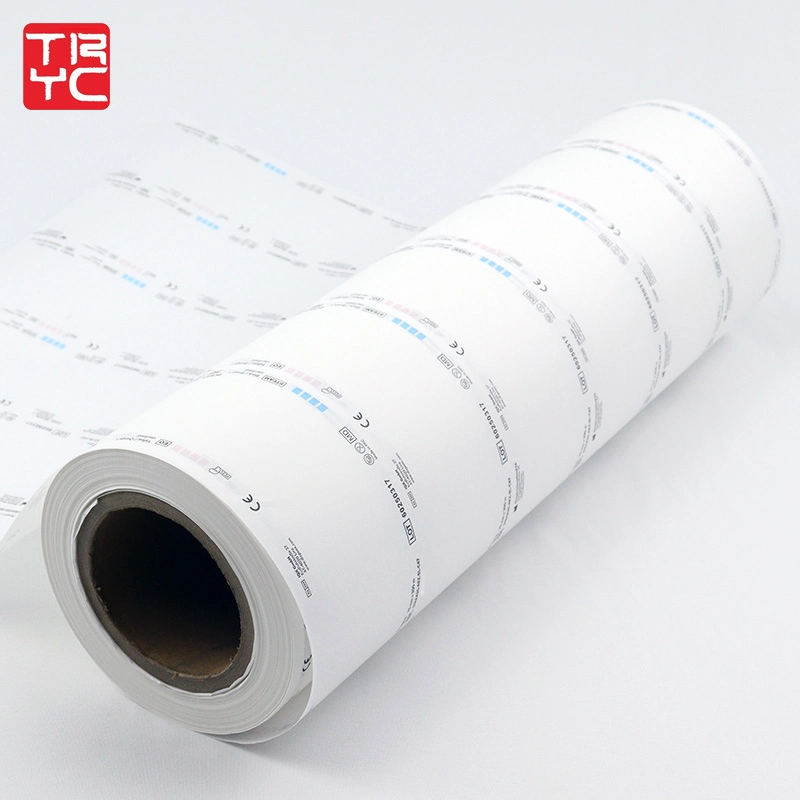

Many films are designed to be compatible with various sterilization methods, such as EtO (ethylene oxide) or irradiation.

Sealing Capabilities:

They can be sealed to various lidding materials, including coated and uncoated paper, Tyvek, and other films.

Material Options:

PP/PE; PA/PE; PP/PA

Examples of Applications:

Single-use medical devices: Syringes, cannulas, surgical sets, dental kits.