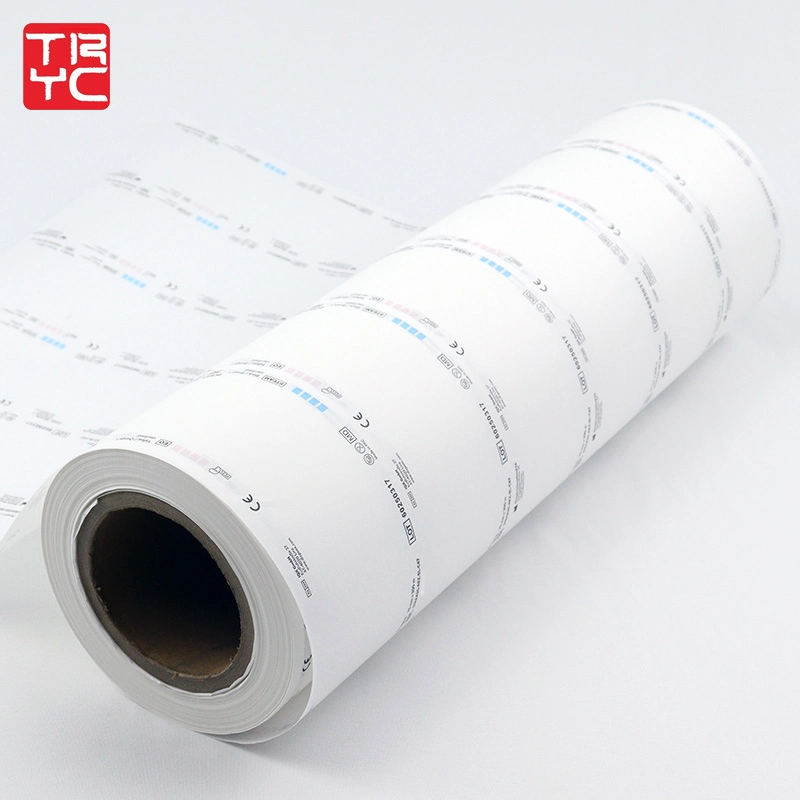

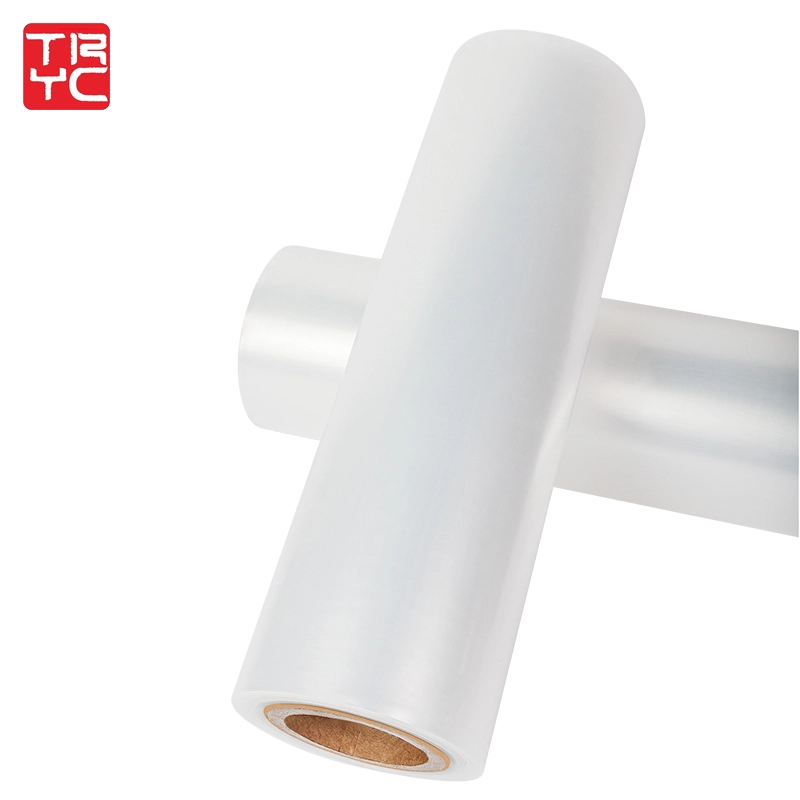

- Product Name: Medical Paper for Pouches and Reels

- Main Gram: 60-80 gsm

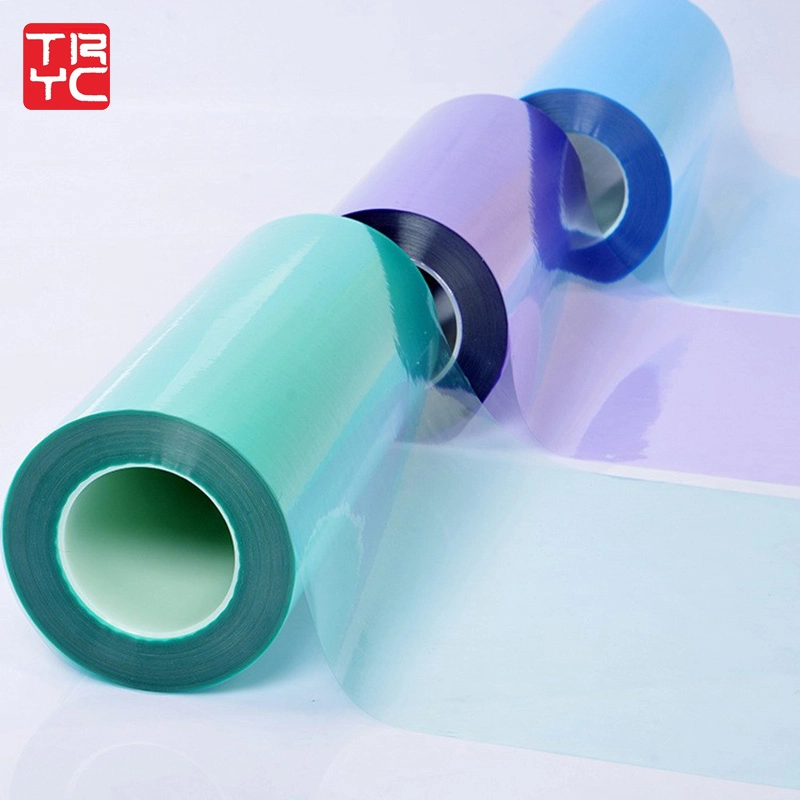

- Sealable Film: PET/CPP

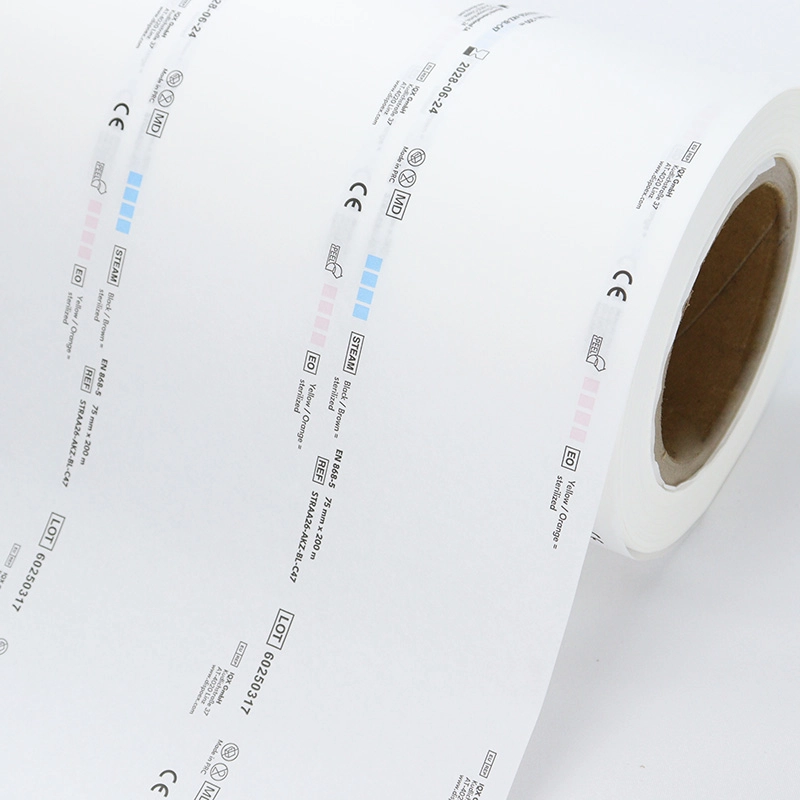

- Sterilization Method: EO / Steam/ Formaldehyde Sterilization

- Features: to make sterilization pouches and reels

Description

Medical direct seal paper is a specialized paper product used in medical device packaging. It’s designed to be heat-sealed directly to other materials, creating a sterile barrier that protects medical instruments during sterilization and storage. This paper offers a cost-effective and efficient solution for various sterilization methods, including Steam, EtO (ethylene oxide), and Formaldehyde.

Sterile Barrier:

Direct seal paper provides a barrier against microbial contamination, maintaining sterility of the packaged medical device.

Direct Sealability:

It can be sealed directly to itself or other materials, eliminating the need for additional adhesives or tapes.

Sterilization Compatibility:

It is compatible with various sterilization methods like steam, EtO, and Formaldehyde, making it a versatile packaging material.

Clean Peel:

The paper is designed to peel cleanly and easily from the sealed package, minimizing the risk of fiber tears or particulate contamination during opening.

Cost-Effective:

Direct seal paper offers a cost-effective solution for packaging medical devices, especially for high-volume production.

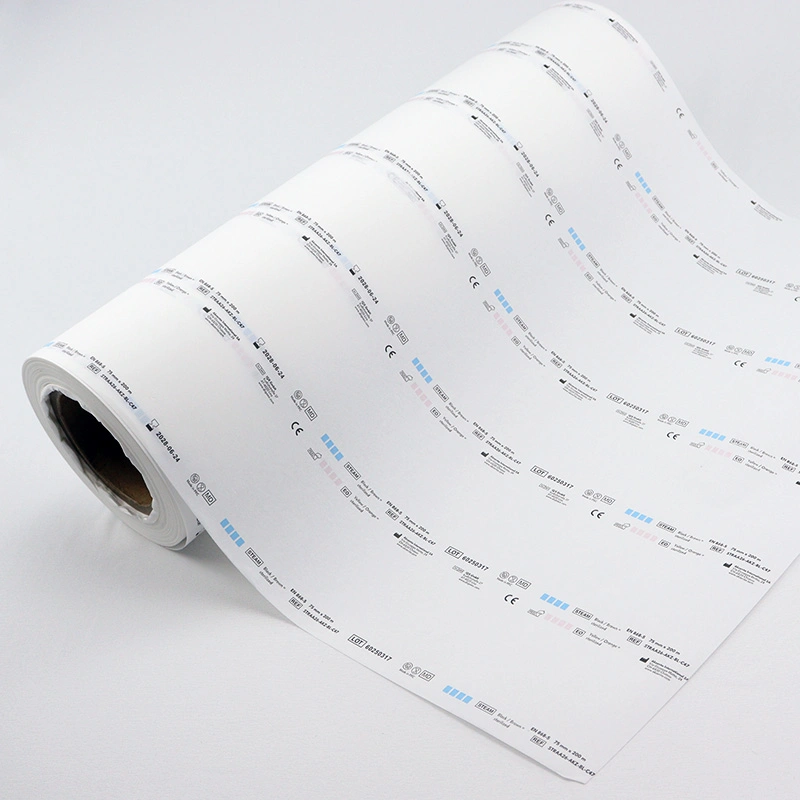

Printability:

The paper surface is suitable for printing, allowing for clear labeling and information display.

Applications:

Available in various formats like pouches and reels for automated packaging processes.

Specific Application Needs:

The choice of paper grade and material depends on the specific sterilization method and the type of medical device being packaged.

Regulatory Compliance:

Ensure the chosen paper complies with relevant standards like EN 868 and ISO 11607.