Medical CPP/PET film is a multi-layer composite film used in medical packaging, known for its durability, moisture resistance, and ability to withstand sterilization. It's made of a combination of PET (polyethylene terephthalate) and CPP (cast polypropylene) films, offering a good balance of properties for various medical applications.

Description

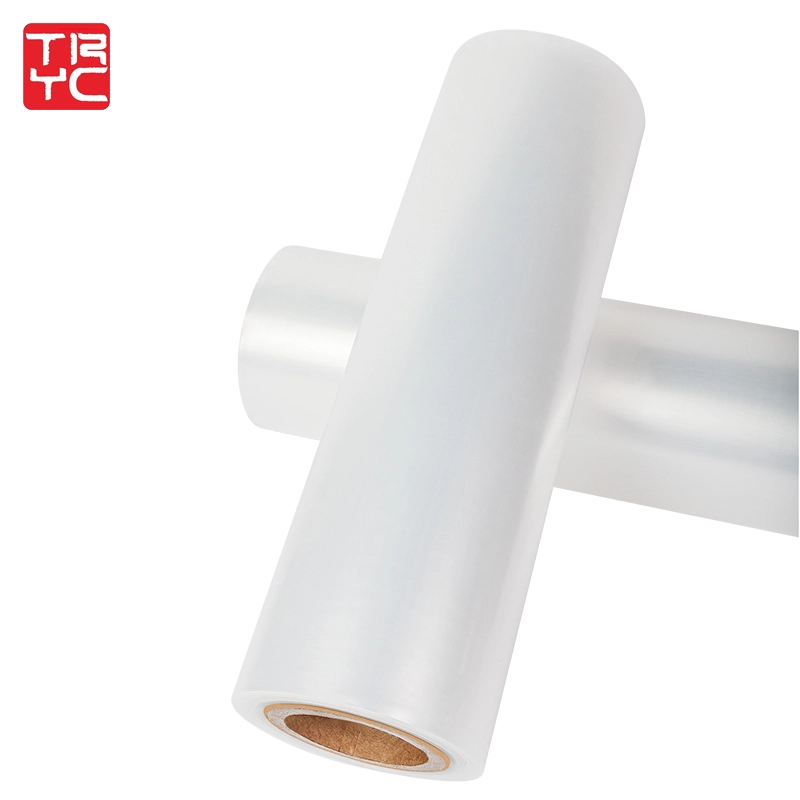

High Clarity and Gloss:

PET/CPP film offers excellent clarity, allowing for easy identification of the packaged contents.

Moisture and Sterilization Resistance:

It’s moisture-proof and can be sterilized using steam, EO (ethylene oxide), or formaldehyde, making it suitable for sterile packaging.

Durability and Strength:

The film provides good puncture, tear, and break resistance, crucial for protecting medical devices.

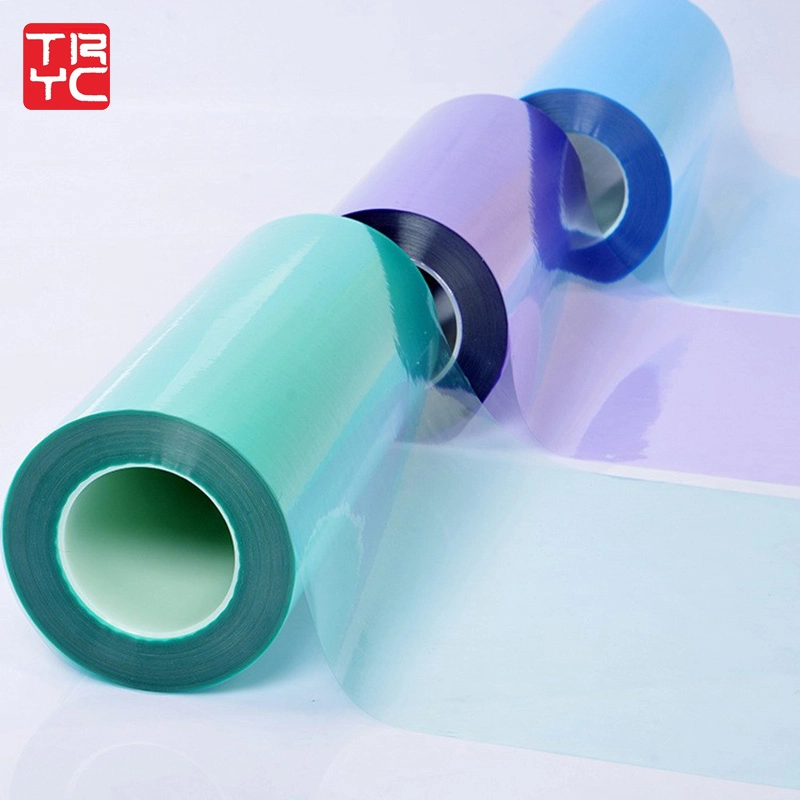

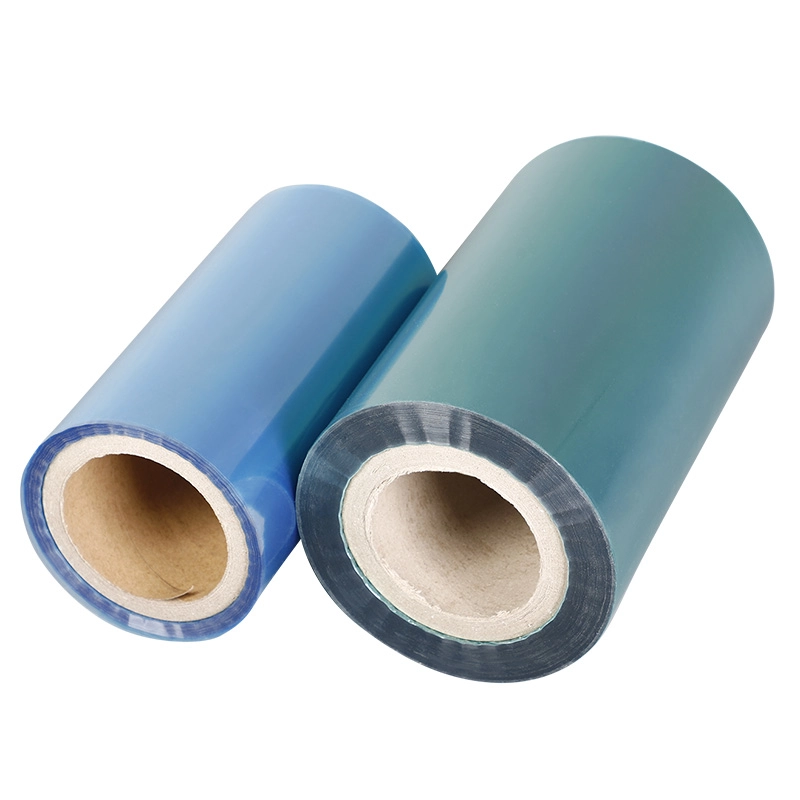

Customizable:

It’s available in various colors (green, blue, purple, white) and sizes, with customizable widths and thicknesses, allowing for tailored solutions.

Applications:

Common uses include sterilization pouches and reels for medical equipment, packaging for surgical instruments, and other medical device packaging.

Material Composition:

PET (Polyethylene Terephthalate): Provides strength, clarity, and temperature resistance.

CPP (Cast Polypropylene): Offers good heat-sealing properties, flexibility, and moisture barrier.

Key Performance Features

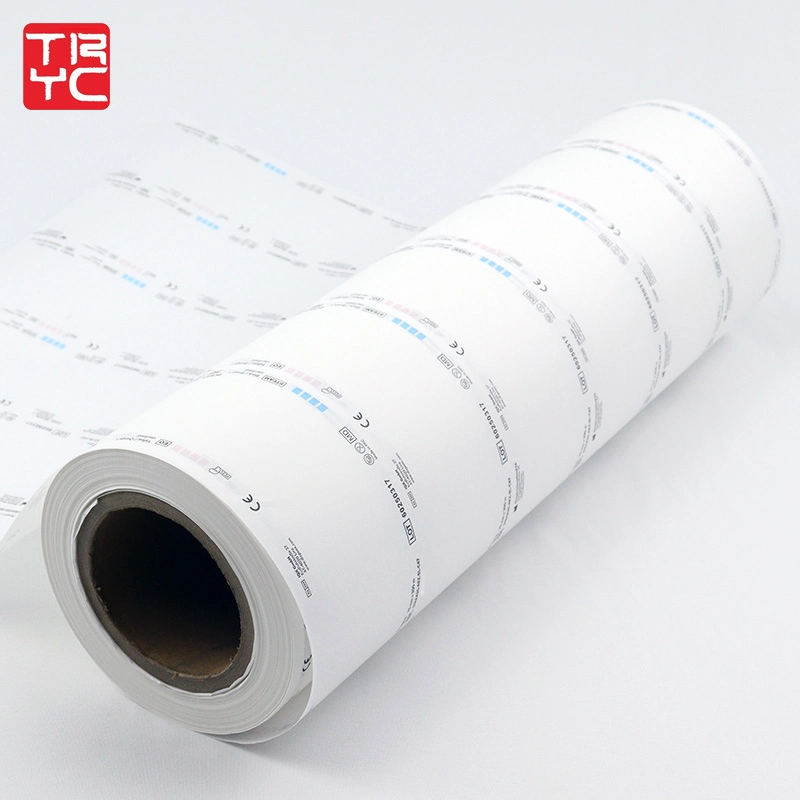

High Transparency: Optimized PET layer provides excellent clarity for easy visual inspection of sterilized medical devices.

Superior Seal Strength: The CPP (Cast Polypropylene) inner layer ensures a wide sealing temperature range and strong, burst-resistant seals.

Excellent Barrier Properties: Engineered to provide a consistent microbial barrier and moisture resistance, ensuring the long-term sterility of packaged contents.

Uniform Thickness: Advanced co-extrusion technology ensures thickness consistency, which is critical for high-speed automated packaging lines.

Application Scenarios

Form-Fill-Seal (FFS) Packaging: Ideal for automated packaging of disposable syringes, needles, and infusion sets.

Medical Pouch Production: Used as the plastic film side for sterilization pouches and reels (combined with medical paper or Tyvek).

Protective Packaging: Suitable for larger surgical kits and laboratory consumables requiring a durable, puncture-resistant barrier.

FAQ

Q1: What are the benefits of using CPP over PE in medical laminated films?

A1: CPP (Cast Polypropylene) offers higher temperature resistance and better clarity compared to PE. It provides a more rigid structure and superior peelability, making it ideal for medical kits that require a “clean peel” without fiber tearing.

Q2: Is TRYC CPP/PET film compatible with EO sterilization?

A2: Yes. Our medical laminated films are specifically designed to withstand Ethylene Oxide (EO) and Gamma Radiation sterilization processes without compromising the seal integrity or film clarity.

Q3: Can this film be customized for different thickness requirements?

A3: Absolutely. We offer customizable thickness ranging from 52 micron to 100 micron to meet the specific requirements of different medical device weights and packaging machines.