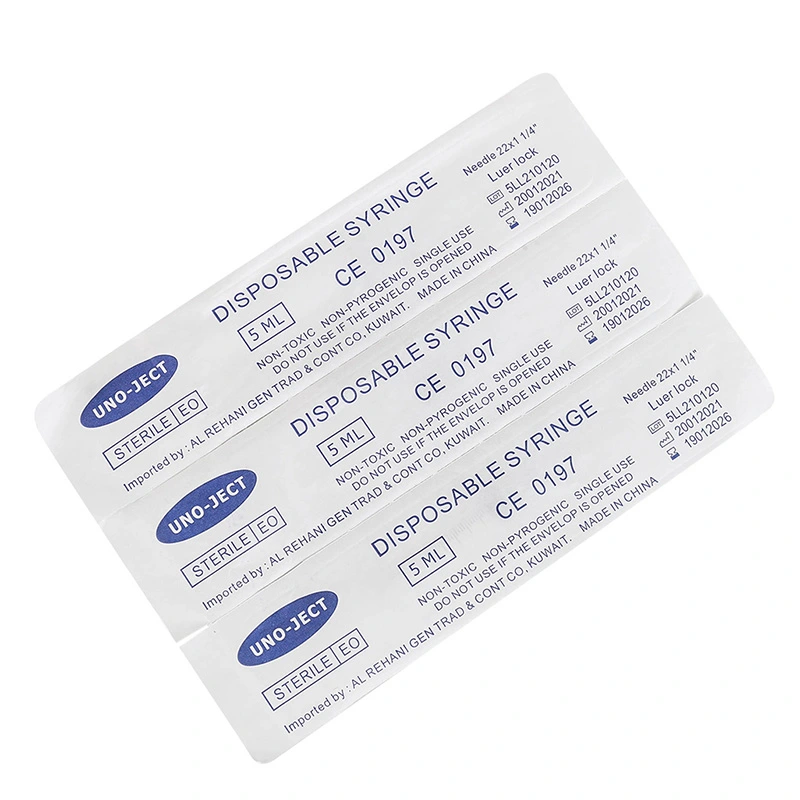

TRYC Blister Syringe Packaging

Description

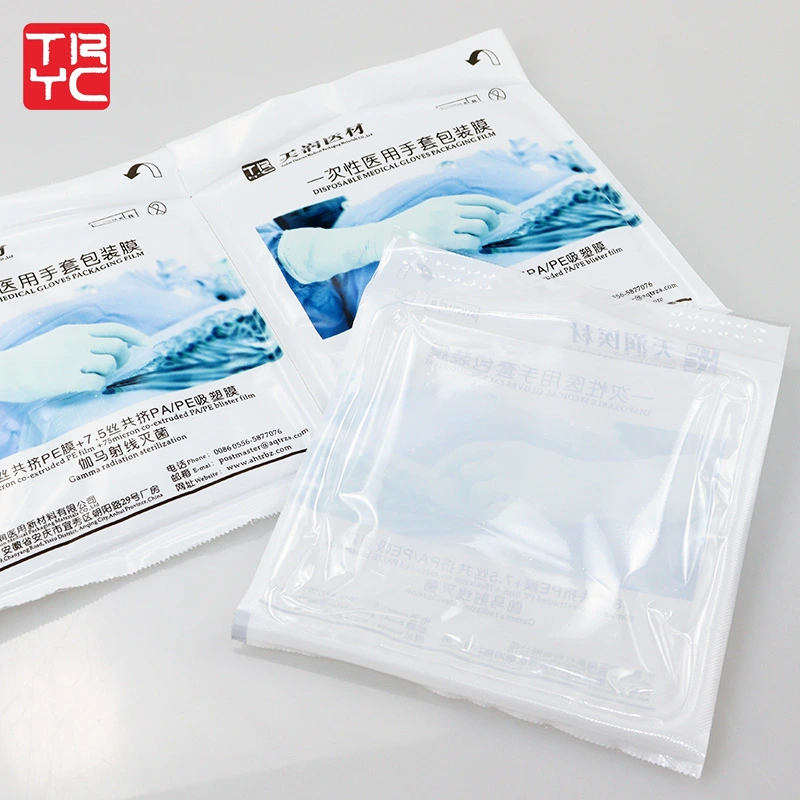

Blister packaging means placing a product in a blister pack which is a molded cavity covered with a transparent plastic film or aluminum foil. This packaging style employs PVC, PET, or aluminum to form a protective shield that will shield the product from influences from outside. Blister packaging is most frequently used for tablets, capsules, and other pharmaceuticals, electronics, and cosmetics, where visibility and protection are important. However, where is blister packaging most commonly used, and why has it become so popular? In this article, the author discusses the use and functions of blister packaging, the classification of blister packaging, the benefits of blister packaging, and how blister packaging is used in industries in today’s packaging world.

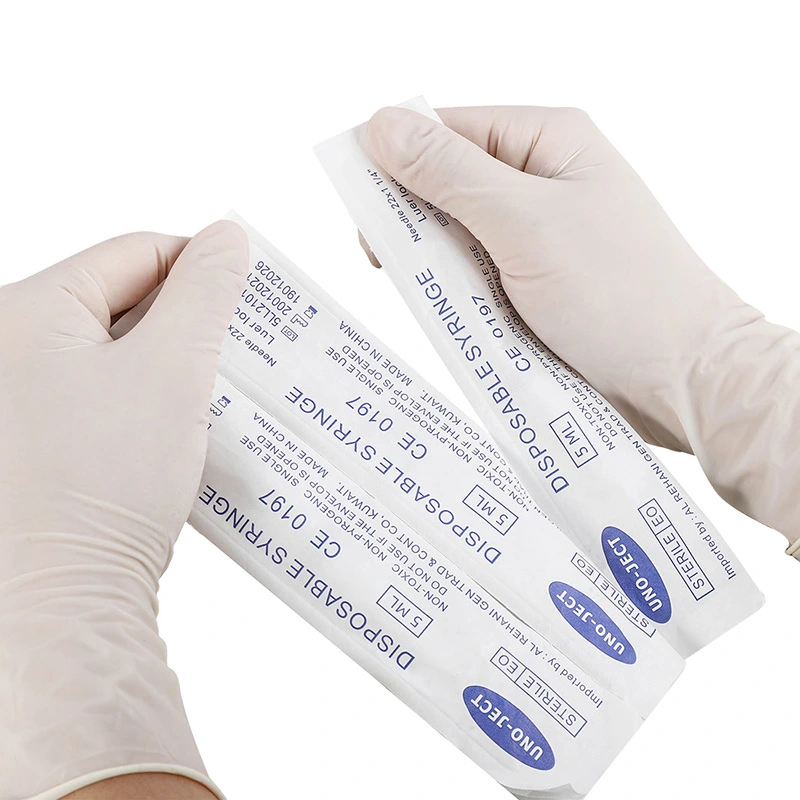

In blister packaging, one forms a depression in the blister pack, that would allow it to encompass the product, then covers it with the lidding material, normally a plastic film, aluminum foil, or both. Manufacturing processes of blister packaging include forming, filling, sealing, and cutting and provides a barrier against moisture, contaminant, and shock in addition to aesthetical appeal to the product. From the protection of drugs to offering theft proof hinged covers for electronics, blister packaging plays a significant function in many fields.

Blister packaging is a thermoforming process where a plastic film or sheet is heated to make it flexible before being shaped by high pressure (4-8 bar) into the cavity of the packaging. The formed mold is then cooled to a temperature that enables the plastic to maintain the formed shape once the mold is opened. For more complicated shapes or for larger ones, an “assist plug” is utilized to guarantee equal wall thickness. Thermoforming is commonly used for packaging small objects such as tablets, since it is quick, effective and forms a clear, strong barrier.