- Authentication of seal integrity

- Documentary evidence for future internal and external audits

- Easily identifiable if one of the heat seal parameters is not functioning correctly

- Reduced wastage of pouches and reels

- Easy to use

Description

TRYC Instruction Manual

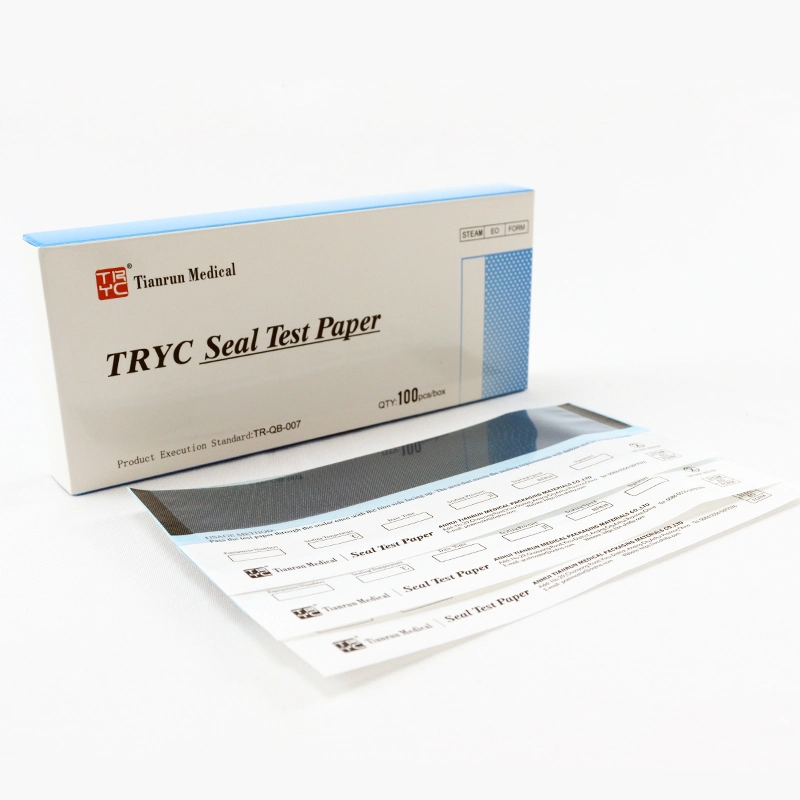

- Product name:TRYC Seal Test Paper

- Model:TRPL

- Description:This product is for single use only.The TRYC brand seal test paper is made of imported plasma dialysis paper It has consistent physical, chemical,mechanical and bacteria barrer properties with the materials used in TryC brand hydrogen peroxide low-temperature plasma sterilization packaging bags and peracetic acid low-temperature sterilization packaging.The sealing effect of the sealing equipment verified by it is consistent with the actual sealing effect of paper-plastic packaging bags.

- Principle of product: The principle of the seal test paperis to judge whether the peel strength of the paper-plastic packaging bag meets the requirements based on the visual perception of the sealed area before and after heat sealing.The black printed area of the seal testpaperhasclearlyandevenlydistributed white spots. After heat sealing,if the color of the sealed area darkens and the white/black spots are clearly and evenly distributed, it indicates that the film and paper are tightly sealed and the sealing equipment is in good condition; if there is no change in the color of the sealed area or the white/black spots are indistinctly and unevenly distributed, it means that the film and paper are not completely bonded.

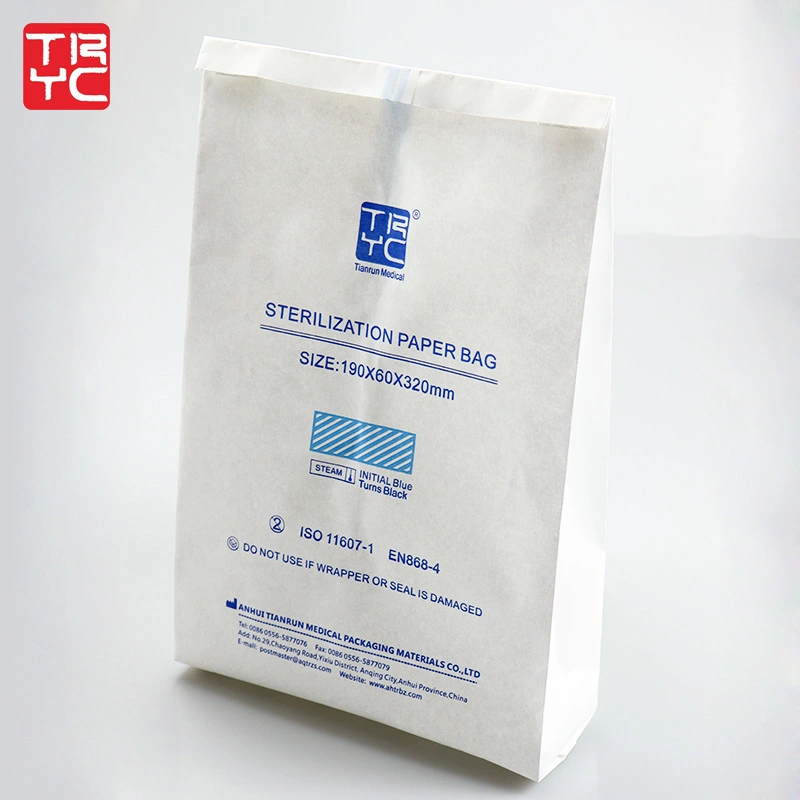

- Scope of use

It is used to test the heat-sealing peformance of medical sealing equipment on TRYC brand hydrogen peroxide low-temperature plasma sterilization packaging bags and peracetic acid low-temperature sterilization packaging bags. - Méthode d'utilisation

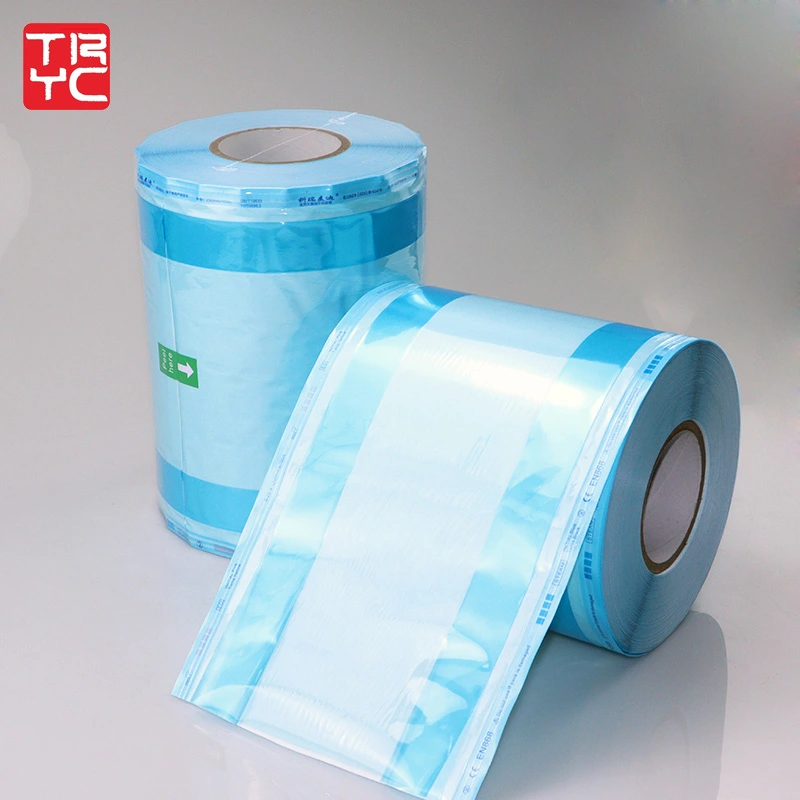

Sealing temperature, pressure and speed of the equipment greatly affect the sealing strength of paper-plastic packaging bags. Recommended sealing temperature:110~200℃; pressure:refer to the sealer; speed:1Om/min.After the temperature stabilizes,take a seal test paper,passit through the sealer once with the film sideup,and observethe sealed area. Darkened color there with evenly distributed white/black spots indicates tight sealing and good equipment performance. - IPrecautions:

1,This product can only be used once.

2,Avoid contamination on the surface of the test paper.

3,Store in a moisture-proof,well-ventilatedandlight-proofplace.

Validity period: 36 months

Production date and batch number are indicated on the product packaging.