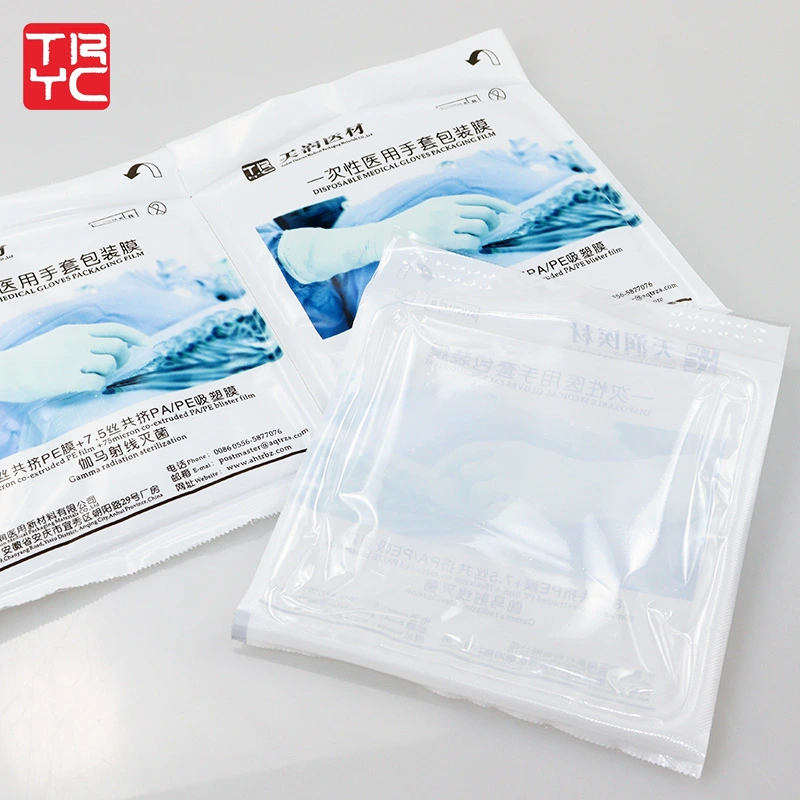

Medical PE (polyethylene) packaging refers to packaging materials made from polyethylene, a versatile plastic widely used in the medical industry for its protective and sterilizable properties. It's used to create sterile packaging for medical devices, instruments, and supplies, ensuring they remain contamination-free until use.

وصف

Key Properties of Medical PE Packaging:

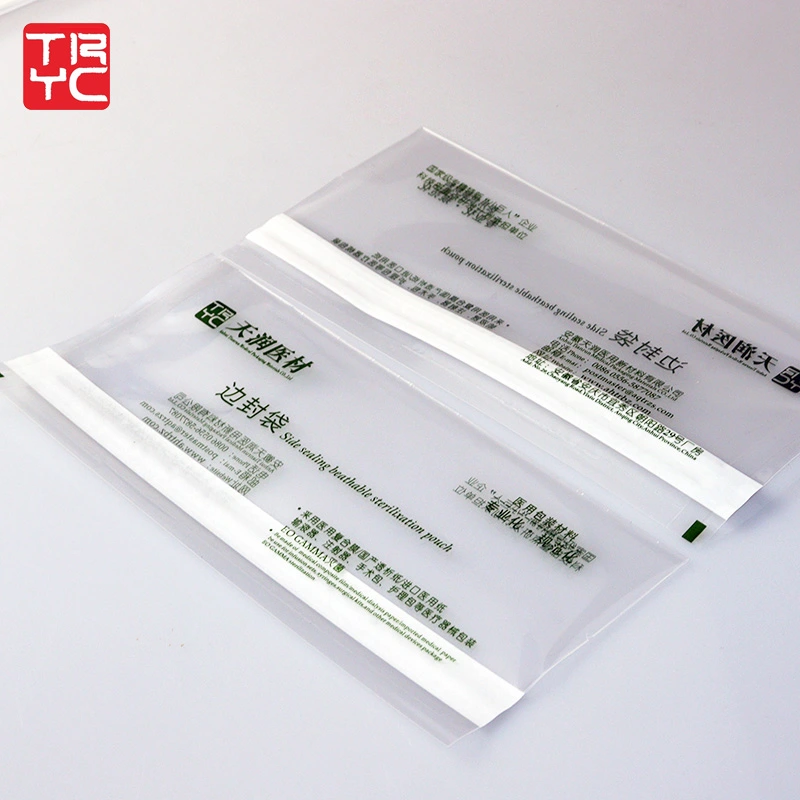

Sterilizability:

PE packaging can be sterilized using methods like ethylene oxide (ETO) or irradiation, ensuring a sterile environment for medical devices.

Barrier properties:

PE provides a barrier against moisture, germs, and tampering, protecting the contents from contamination.

Durability and puncture resistance:

PE is a strong and durable material, able to withstand handling and transportation without compromising sterility.

Flexibility and transparency:

PE film can be easily shaped and molded for different packaging needs, and its transparency allows for visual inspection of the contents.

Biocompatibility:

PE is considered biocompatible, meaning it’s safe for contact with the human body, making it suitable for direct contact with medical devices and implants.

Cost-effectiveness:

PE is a relatively inexpensive material, making it a practical choice for both single-use and reusable medical packaging.

التطبيقات:

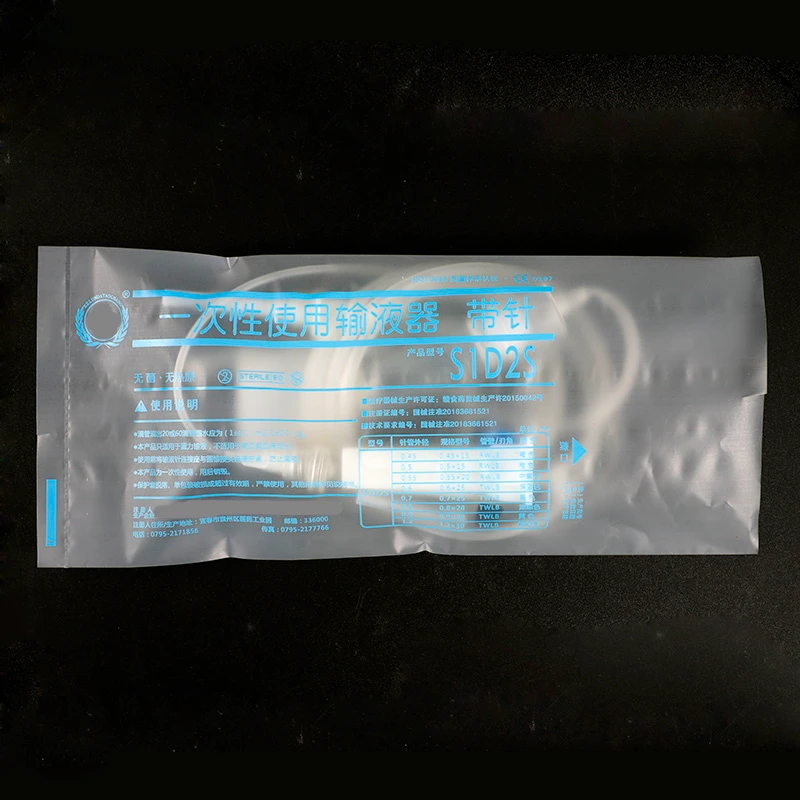

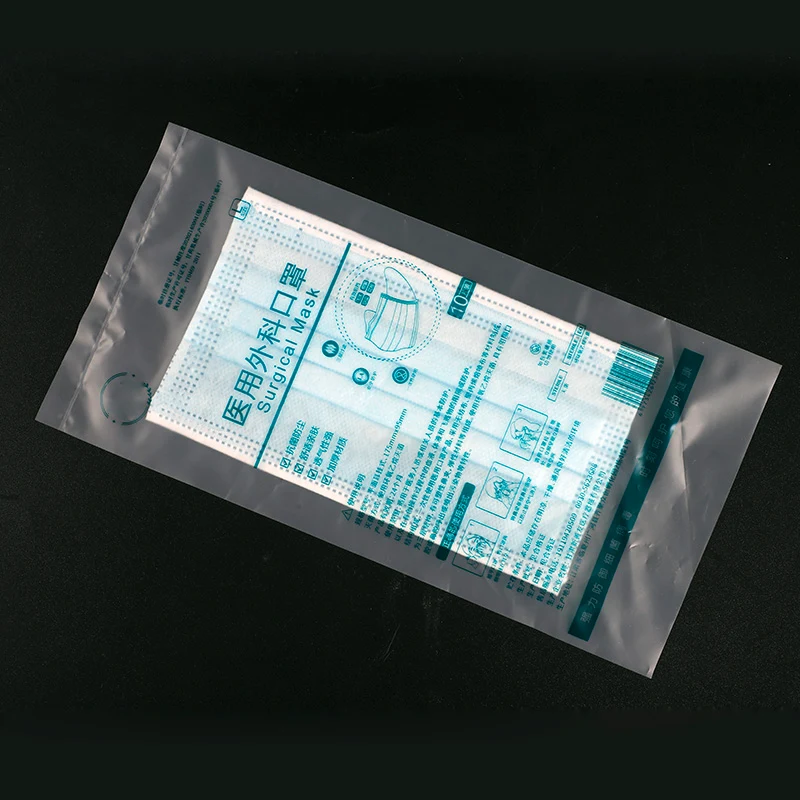

Sterile packaging for medical devices: Ensuring syringes, catheters, surgical instruments, and other devices remain sterile until use.

Packaging for pharmaceuticals: Protecting medications and other pharmaceutical products from contamination and degradation.

Medical bags and pouches: Storing and transporting fluids, medications, and other medical supplies.

Drape sheets and protective clothing: Maintaining a sterile environment during surgical procedures and protecting healthcare workers.

Implants and prosthetic components: Using PE in implants and prosthetic devices due to its biocompatibility and durability.

Medical tubing: Providing flexibility and safety for fluid transfer systems.