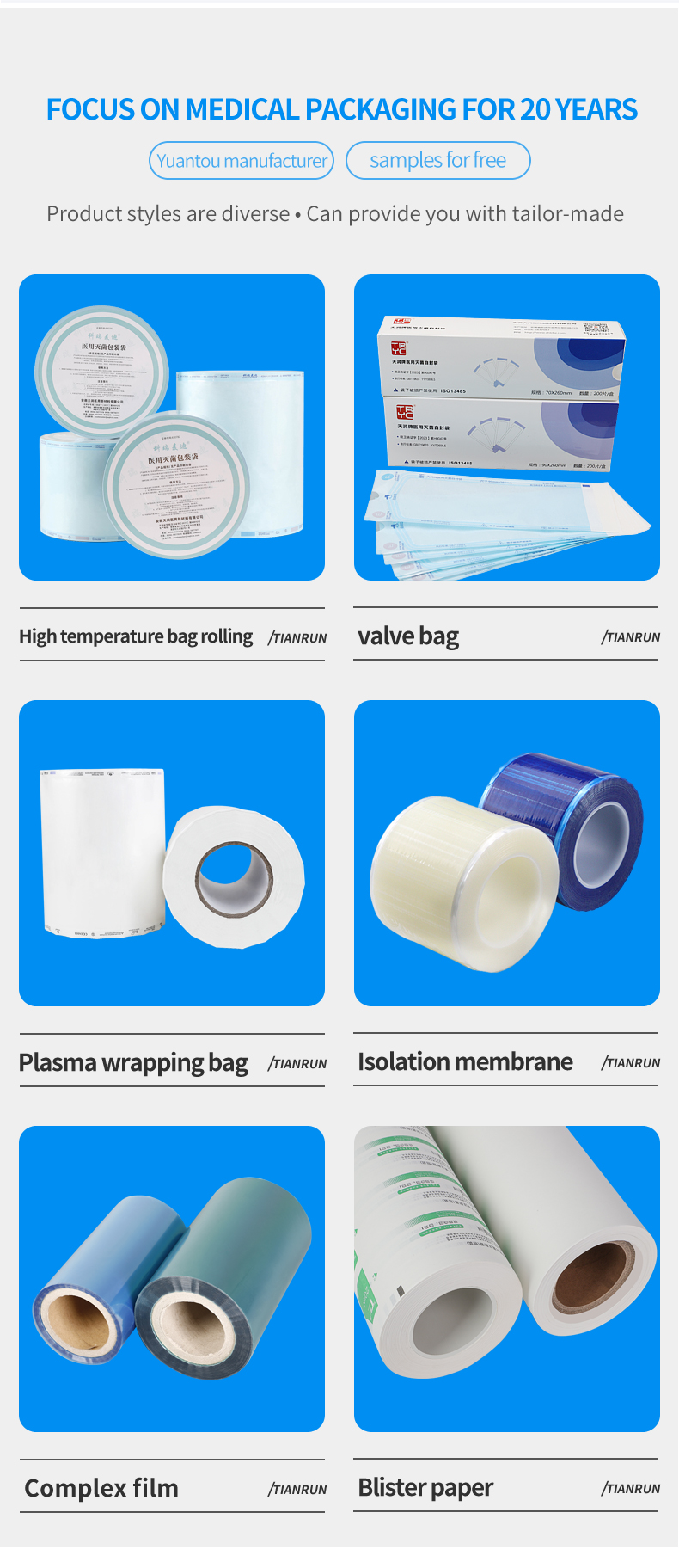

Sterilized nonwoven fabric

2024/4/12

![]()

Product parameters:

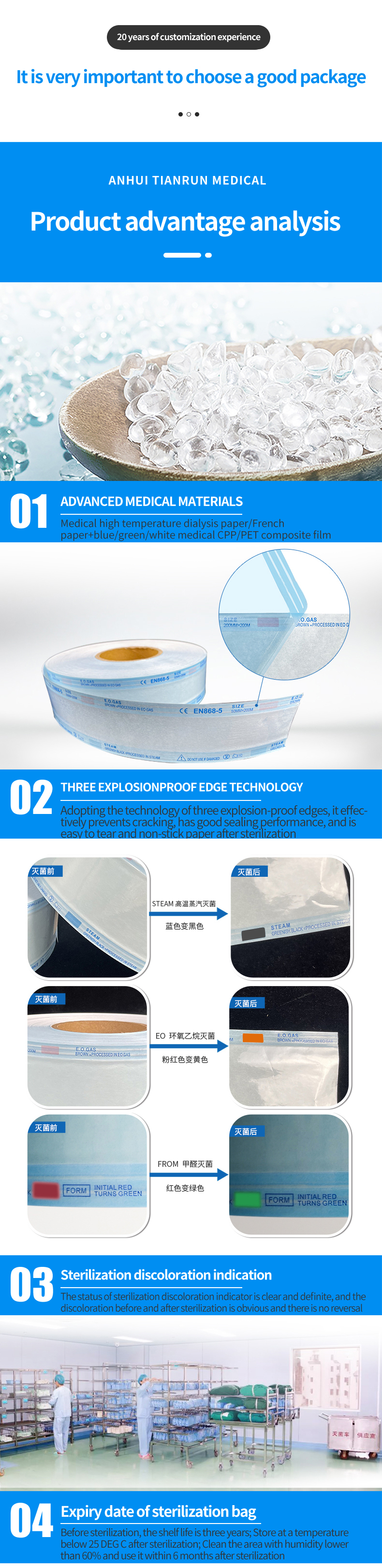

Sterilization principle: during the sterilization of medical devices, the sterilizing agent can effectively penetrate SMMMS non-woven packaging materials to achieve the expected sterilization effect, and the non-woven packaging materials provide an effective microbial barrier, which makes the devices sterile after sterilization.

Product structure: SMMMS

Product color: blue, green, white, pink, other

Applicable sterilization methods: pressure steam sterilization, ethylene oxide sterilization and hydrogen peroxide sterilization.

Usage: Choose non-woven packaging materials with appropriate specifications according to the size of sterilized articles, put the articles in the packaging materials, pack them in double layers, wrap them with sterilization indicator tape (10-20CM), and then store them in a sterilizer for sterilization as required.

Shelf life after sterilization: 180 days

Product safety: Medical grade materials meet the requirements of biocompatibility.

Storage method: store at room temperature (about 20℃) and 50% relative humidity; Avoid sunlight and ultraviolet rays.

Product features:

Safety: It is spun with brand-new polypropylene raw materials, without fiber shedding.

Convenience: it is suitable for various sterilization methods, and the product is light and soft, which is convenient for handling and operation, and improves working efficiency.

Economical: no need to recycle and clean. Easy to recycle, saving department expenses.

Diversity: specifications can be customized according to customer needs.

Product parameters:

Sterilization principle: during the sterilization of medical devices, the sterilizing agent can effectively penetrate SMMMS non-woven packaging materials to achieve the expected sterilization effect, and the non-woven packaging materials provide an effective microbial barrier, which makes the devices sterile after sterilization.

Product structure: SMMMS

Product color: blue, green, white, pink, other

Applicable sterilization methods: pressure steam sterilization, ethylene oxide sterilization and hydrogen peroxide sterilization.

Usage: Choose non-woven packaging materials with appropriate specifications according to the size of sterilized articles, put the articles in the packaging materials, pack them in double layers, wrap them with sterilization indicator tape (10-20CM), and then store them in a sterilizer for sterilization as required.

Shelf life after sterilization: 180 days

Product safety: Medical grade materials meet the requirements of biocompatibility.

Storage method: store at room temperature (about 20℃) and 50% relative humidity; Avoid sunlight and ultraviolet rays.

Product features:

Safety: It is spun with brand-new polypropylene raw materials, without fiber shedding.

Convenience: it is suitable for various sterilization methods, and the product is light and soft, which is convenient for handling and operation, and improves working efficiency.

Economical: no need to recycle and clean. Easy to recycle, saving department expenses.

Diversity: specifications can be customized according to customer needs.

Anhui Tianrun Medical Packaging Materials Co., Ltd Property in copyright Anhui ICP 2024032324 {Disclaimer}