B-D test package

2024/4/12

Product name: BD test package

Gauge: product size 115*125mm.

Shape: square

Sterilization method: pressure steam sterilization

Processing customization can be provided

[Validity] 18 months

"Scope of use" is used to test the air removal effect of the pre-vacuum pressure steam sterilizer.

This product contains B-D test paper, laminated sheets and foam sheets, and the outer bread has a crumpled paper and is packaged by an indicator label. B-D test paper is printed with steam-sensitive indicating ink, which is placed near the center of laminated materials. During sterilization, steam can penetrate the laminated materials with good air permeability and react with the indicating ink on the B-D test paper, so that the B-D test paper changes from yellow to black. Under normal circumstances, the pattern on the B-D test paper will turn uniform dark brown to black when the sterilizer is operated at 132℃ or 134℃ for 3.5 minutes. If the cold air is removed, the cold air in the bag will affect the penetration of steam, making the center of the B-D test paper form a light-colored area different from the surrounding area, thus reflecting the removal effect of the sterilizer on cold air. The indicator label on the outside of the test bag is also printed with steam-sensitive indicator ink, which turns from yellow to black after steam sterilization, indicating that the test bag has been used.

【method of application】

1. The sterilizer is preheated to a suitable temperature.

2. In the case of an empty pot, place the test package above the exhaust

port, near the door, with the label facing up and flat.

3. When the sterilizer is operated for

3.5 minutes (132℃ or 134℃), any

overtime work will affect the B-D test results. If the sterilizer is

operated for more than 4 minutes, the sensitivity of the test paper will

decrease, and false negative results will be observed.

4. After the cycle, check the BD test paper.

5. Interpretation method: After passing, the BD test paper becomes uniform dark brown to black, and the BD test is qualified at this time; Failure, there is a bright area in the middle of BD test paper, the color is uneven, and BD test is unqualified, so follow-up treatment should be carried out according to the requirements of national standards. Passing result: B-D test paper turns into uniform dark brown to black, which is the passing test result. It shows that the air in the sterilizer is removed and the steam penetration effect is good. The result of failure: there is a bright area in the middle of the twill of B-D test paper, which shows uneven color, which is caused by the cold air mass in the sterilizer room, indicating that the air is removed and the effective penetration of steam is prevented. If uneven color change is found, it must be reported to the supervisor immediately, and the sterilizer must be repaired until it is qualified for troubleshooting. Overexposure: If the test paper is gray or silver, it means overexposure (the time or temperature exceeds the standard), which means that the test is invalid and needs to be retested.

![]()

![]()

![]()

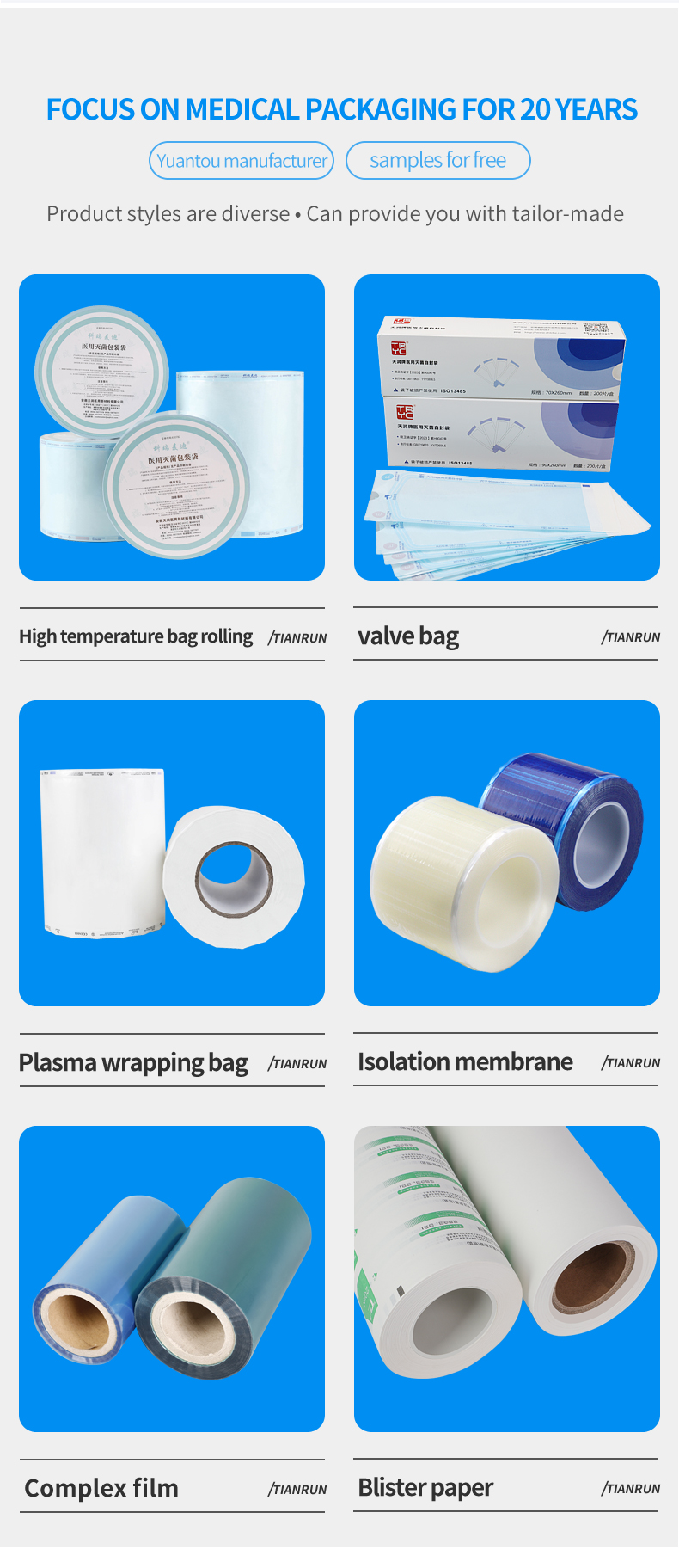

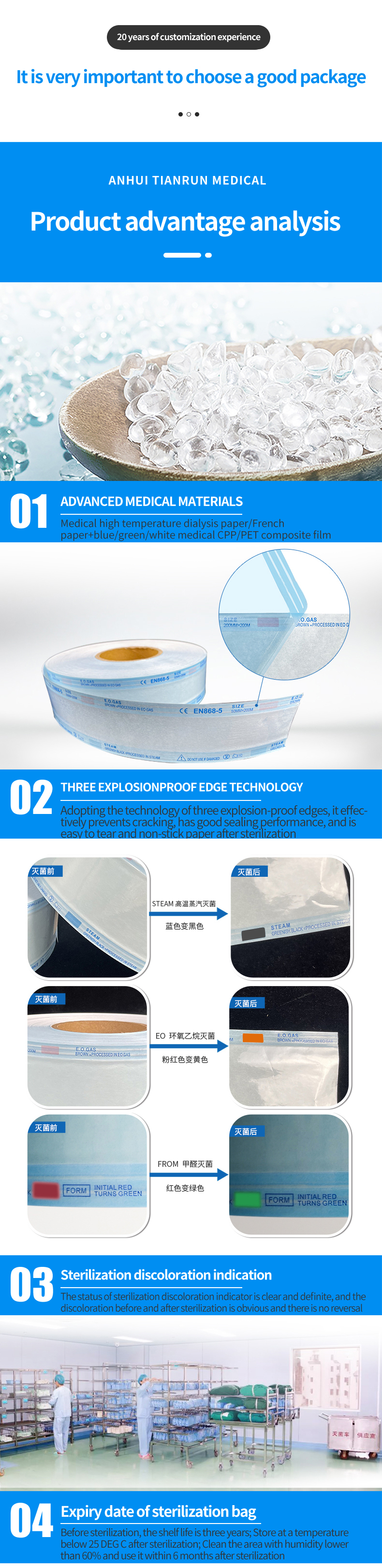

Anhui Tianrun Medical Packaging Materials Co., Ltd Property in copyright Anhui ICP 2024032324 {Disclaimer}